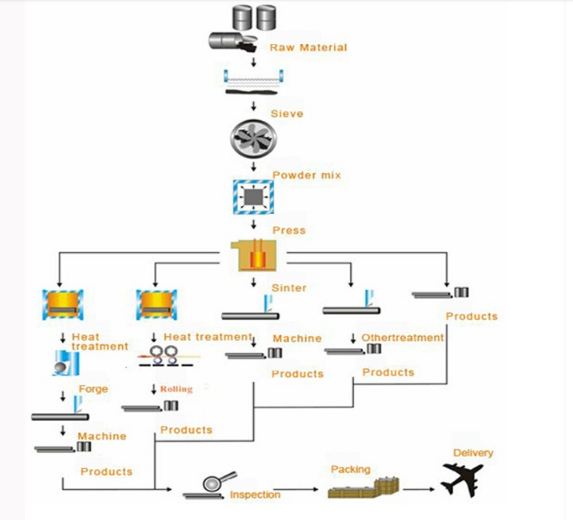

Process Flow Chart:

Product Name: Tungsten Rod/ Tungsten Bar/ Tungsten Electrode

Grade: W1

Purity: W≥99.95%,

Density≥19.3g/cm3

Quality Standard: JB4730-94 & ASTM standard

Surface: black surface, alkaline cleaning surface, machined surface, polished and grind surface;

Dimensions:

|

Product Name |

Diameter |

|

Tungsten Wire |

≥0.7mm |

|

Tungsten Rod |

0.5mm—3.0mm |

|

Rotary Forging Tungsten Rod |

3.0mm-25mm |

|

Forging Tungsten Rod |

25mm-100mm |

|

Sintering Tungsten Rods |

≤150mm |

Quality Requirements:

Surface of forged Tungsten rod can be allowed to have oxidation film and slight traces of forging;

Surface of bright finished Tungsten rod shows metallic luster, no significant oxidation phenomenon;

Both the surface of Tungsten Rod without layering, crack, burr, longitudinal crack and other defects;

Application

Tungsten rod has special properties, such as low thermal expansion and good thermal conductivity, enough resistance resistance, high modulus of elasticity. So the tungsten rods are widely used in various fields, such as support of wires, lead in wire, printer needle, all kinds of electrodes and quartz furnace, filament, high-speed tools, automobile automatic products, sputtering target materials, tungsten contact and electric light source components.

Luoyang Rare Metal Research Material Co.,Ltd

Packaging Service:

1) Standard wooden cases with plastic bags inside.

2) Three-ply or plywood,fumigation-free.

3) As the clients requirement.

Delivery Service:

10~15 days working days.

Shipping:

We usually transport by TNT, FEDEX, UPS, DHL ect.

Sample Service:

Customized the samples according to customers’ requirements.